Unlocking the Mysteries of Magnetite: A Deep Dive into Selective Minerals for Magnetite Powder

Magnetite, a captivating mineral with magnetic allure, holds within its crystalline structure the key to a myriad of industrial applications. Composed of iron oxide (Fe3O4), magnetite is celebrated not only for its aesthetic black sheen and metallic luster but also for its significant presence in diverse geological settings.

Magnetite, a captivating mineral with magnetic allure, holds within its crystalline structure the key to a myriad of industrial applications. Composed of iron oxide (Fe3O4), magnetite is celebrated not only for its aesthetic black sheen and metallic luster but also for its significant presence in diverse geological settings.

Understanding Magnetite:

Magnetite’s magnetic properties are a result of its unique atomic arrangement, making it one of Earth’s most abundant magnetic minerals. This remarkable mineral is found in various geological environments, from igneous rocks and hydrothermal veins to sedimentary deposits. Its magnetic qualities have earned it a place of prominence in both natural formations and industrial processes.

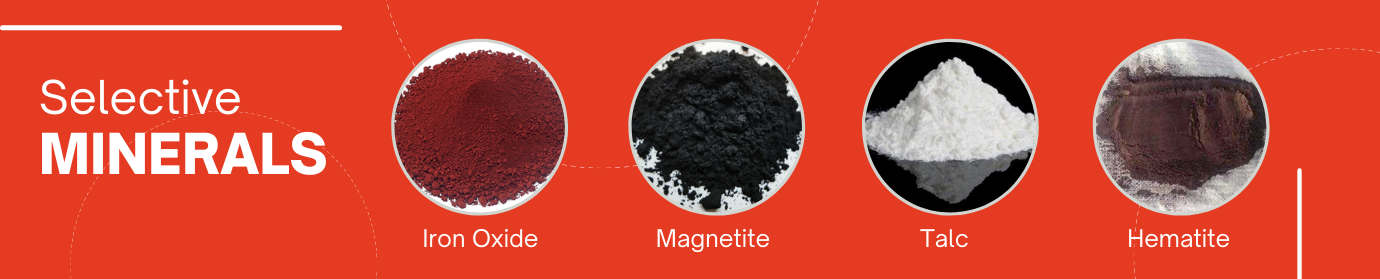

Selective Minerals for Magnetite Powder:

The journey from magnetite-rich ores to high-quality magnetite powder involves a meticulous process of selective mineral extraction. This careful curation is aimed at ensuring the powder meets rigorous standards of purity and quality for its myriad industrial uses. The selective minerals chosen contribute to the powder’s suitability for applications ranging from heavy media separation to catalyzing chemical reactions.

Industrial Applications:

Heavy Media Separation (HMS):

Magnetite powder plays a pivotal role in heavy media separation processes, particularly in mining and coal washing. Its high density allows for the separation of valuable materials from waste based on density disparities.

Iron Ore Processing:

As an iron ore, magnetite is a crucial component in the production of iron and steel, supporting the foundational elements of global industrial infrastructure.

Drilling Fluids in Oil and Gas Industry:

The unique properties of magnetite powder find application in drilling fluids for oil and gas wells, aiding in controlling drilling mud viscosity and preventing well wall caving.

Catalysts in Chemical Reactions:

Leveraging its magnetic and catalytic properties, magnetite powder serves as a catalyst in diverse chemical reactions, contributing to industrial processes.

Environmental Applications:

Magnetite’s role extends to environmental remediation, where its magnetic properties facilitate the removal of contaminants from water, contributing to sustainable water treatment processes.

Magnetite Powder Production:

The journey from mineral extraction to the production of magnetite powder involves a series of steps. Mining, crushing, and milling magnetite-rich ores are followed by magnetic separation processes to refine the powder, ensuring it meets the stringent quality standards demanded by various industries.

Conclusion:

Magnetite, with its magnetic charisma and versatile attributes, emerges as a mineral of profound significance across industries. The careful selection of minerals for magnetite powder production ensures its applicability in an array of industrial processes, contributing to advancements in technology, sustainable practices, and the intricate tapestry of our industrial landscape. As industries continue to harness the potential of magnetite, this mineral not only captivates with its magnetic charm but also stands as a testament to the enduring synergy between nature and innovation.