The industrial applications of Hematite

Hematite is a naturally occurring mineral that is found abundantly around the globe. It is mostly mined out from Earth’s shallow crust.

It is an oxide of iron and its chemical formula is Fe2O3. According to the spokesperson of a leading hematite and magnetite powder supplier in India; hematite is used across all industrial sectors.

hematite powder alongside magnetite powder is considered as two of the most valuable industrial raw materials. Compared to magnetite, hematite ore is known for its tensile strength and hardness. The reason is in its chemical composition. hematite contains a large amount of iron in it thus allowing it to be used as a primary raw material in large, small and medium foundries, metal processing plants and steel beam manufacturing complexes.

Other industrial uses of hematite are as follows –

As an ore for iron

Magnetite powder manufacturers in India does the majority of their business transactions with industrialists who run metal processing plants.

hematite, as already mentioned in the above sections, contains large quantities of iron in diffused form. Furthermore, extracting iron from hematite is pretty easier compared to extracting the metal from other ores.

It is used to produce pigments

Hematite iron oxide manufacturers in India also conduct business with companies associated with the production of paints and related pigments that are used in the construction sector as well as by automobile manufacturers.

The colour of hematite is blood-red hence it is the best raw material for paint and coating manufacturing plants to produce high quality batches of pigments that are then used to produce the final product.

Pigment made using hematite can be used to produce red paints and coatings. At the same time, hematite pigment when mixed with white pigment can be used to produce a plethora of pink coloured coatings and paints.

It is used in heavy media separation

Hematite powder suppliers in India also supplies their products to industrial plants that undertake heavy-media separation projects.

Heavy media separation or sink-and-float separation is carried out when a medium, that is primarily water, is mixed with finely ground heavy mineral like hematite.

The primary application of heavy media separation process is in the mineral processing industry. The process allows plant managers to keep overhead costs down and increase output as well as the efficiency of their plant.

Conclusion

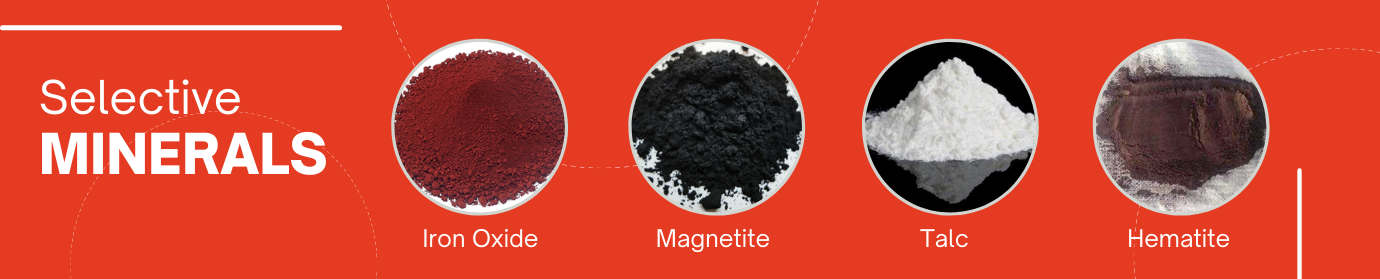

hematite is an ‘in-demand’ industrial raw material which is why one can find countless suppliers for hematite powder but in case one is looking for a supplier that offers high-quality hematite powder at reasonable rates then they should choose Selective Minerals And Color Industries Private Limited. It is an ISO 9001 – 2015 certified enterprise that produces hematite from premium quality ore with more than 95% Fe2O3 content and specific gravity of 5.2. The company has two state-of-the-art mineral processing plants that are paired with quality assurance labs. The company hires only certified professionals with years of experience. To learn more, please call +91-99209 46444 / +91-022-26499343 or send an email at sales@selectiveminerals.com / info@selectiveminerals.com.