What is Black Iron Oxide? What are the Industrial Applications of Black Iron Oxide?

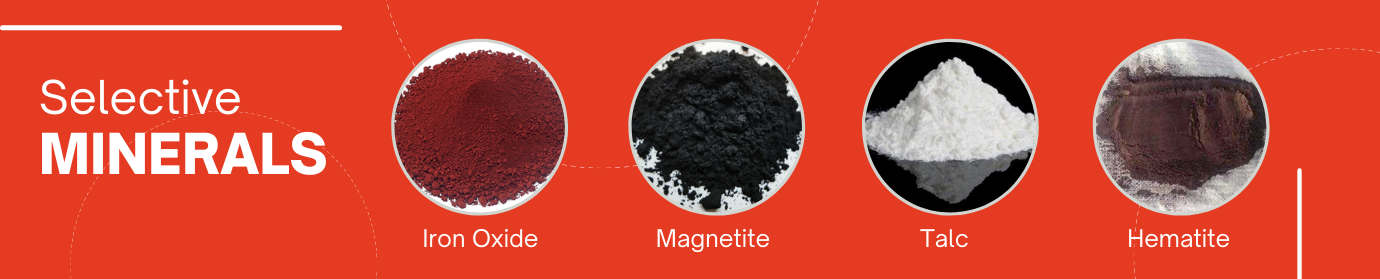

Three naturally occurring minerals have large quantities of iron diffused in them. They are haematite, magnetite and greenalite.

However, magnetite, otherwise known as black iron oxide takes the crown due to the large amounts of diffused iron present in the mineral from the get-go.

Haematite, magnetite and greenalite are all used abundantly across global industrial sectors as –

- Iron catalysts

- Pigments

- Ore, etc.

Even if the above-mentioned minerals are found naturally in abundance, to keep input costs down, industrialists prefer using synthetically produced iron oxide. Iron oxides can be produced synthetically using various processes. Some of the commonly used artificial processes to synthesize iron oxides are –

- Aniline process

- Thermally breaking down iron salts and

- Precipitating iron salts with the help of oxidation.

A global increase in demand for black iron oxide

There has been a tremendous growth in demand for iron oxide in India as well as all over the world. Several independent global market research groups have put forth that the global market share and revenue size for all known oxides of iron had an estimated value of USD 2,319.40 million back in 2021. Experts also point out that this figure will surpass USD 3,020.46 million by the end of 2028. Several new applications of iron oxides have been invented in recent years. This happens to be the driving force behind the global increase in demand for iron oxides.

Furthermore, pigments made using iron oxide entail several hard-to-ignore benefits. For instance, pigments made using iron oxide show an increase in stability as well as strength. This is why when pigments made using iron oxides are further used as an active ingredient in paints, coatings, polymers, construction materials etc. their overall resistance to damages caused by excessive exposure to ultraviolet radiation of sunlight is increased.

Industrial applications of iron oxide

The industrial applications of iron oxide in general are many. Some of the most common ones are mentioned below.

- Iron oxides are mostly used by industrial plants that manufacture specialized paints and coatings for the marine sector, construction sector, automotive sector and aerospace sector.

- Pellets of iron oxides are also used as the raw material needed in the industrial process of shaft furnace smelting.

- Oxides of iron are also used as the primary component in a myriad of pharmaceutical products and plastic products.

- Ink manufacturers also rely on a steady supply of iron oxides.

- Cosmetic product manufacturers also rely on iron oxides especially red iron oxide as it adds a red colour to cosmetic products. Adding iron oxide to cosmetic products is a viable decision due to the non-toxic, weather-resistant, inert and opaque nature of all oxides of iron.

Conclusion

It is no news that several entrepreneurs are opening up ventures that monetize the many advantages of black and red iron oxides. In case the person reading this post is also on the hunt for a reliable iron oxide supplier then they should consider partnering up with Selective Minerals And Color Industries Private Limited. It is one of the leading processed minerals manufacturers, suppliers and exporters from India. The company has been associated with the sector since 1991. The best part, it is an ISO 9001:2015 RINA-certified company. The brand has two state-of-the-art manufacturing and processing plants. The company also benefits from its in-house R&D facilities! To learn more, please call +91-022-26499343 / +91-99209 46444 or send an email to sales@selectiveminerals.com / info@selectiveminerals.com.