What is Iron Oxide? What are the different types of Iron Oxide?

Iron oxide has become an indispensable part of the modern industrial sector. The reason is simple. The many forms of iron oxide act as one of the many primary raw materials industrial plants use to mass produce a plethora of products.

This post, in the following sections, will enunciate what iron oxide is and also explore its many variants. The penultimate section of this post will also shine a light on some primary industrial applications of iron oxide.

What is iron oxide?

Iron oxides are naturally occurring chemical compounds that have oxygen and iron as their primary composition. There are multiple variants of iron oxide and all of them show some degree of magnetic properties.

Iron oxides can also be prepared synthetically by a process known as co-precipitation. When co-precipitation of Fe2+ and Fe3+ takes place and a base is added into the mix, iron oxide is created.

What are the different types of iron oxide?

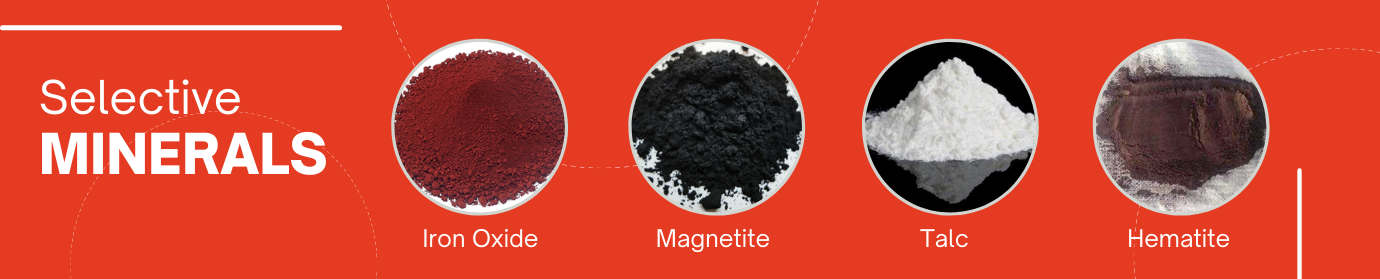

The different types of iron oxide are magnetite, maghemite and hematite.

The colour of magnetite is black. Hence it is also referred to as black iron oxide. The colour of maghemite is yellow. Hence it is also referred to as yellow iron oxide. The colour of hematite is red. Hence it is also referred to as red iron oxide.

The many applications of iron oxides

As already mentioned in the opening paragraphs of this post, iron oxide and its variants find extensive industrial applications all over the globe. Some of the most interesting applications of iron oxide are mentioned in the sections below –

Iron oxides are extensively used in the automobile sector

All automobile manufacturers around the globe rely on suppliers of quality assured iron oxide. The reason is simple. Iron oxide is used as the basecoat for the bodies of automobiles. Apart from increasing the intensity of the final paint job, the iron oxide-containing basecoat also protects the vehicle’s OEM paint job from sustaining damages when the vehicle is subjected to the UV rays of sunlight.

Iron oxide is also used to tint clear coats and lacquers in a bid to enhance their molecular stability. Iron oxide containing lacquers and clear coats are used to paint door handles and wheels of vehicles.

Companies that are engaged in the production of accessories and fitments also rely on a steady supply of iron oxide. For instance, the amber hue of bulbs used in the turn indicators of vehicles is the result of yellow iron oxide added into the mix of glass that will cover the indicator bulb.

Iron oxide is also used as an additive to polymeric fibres – the primary material that is used to produce dashboards, door trims and related plastic parts of a vehicle. Iron oxide is added to the polymeric fibres in a bid to keep the interior plastic surfaces of a modern-day vehicle from sustaining UV damage.

The iron and steel processing sector also relies on iron oxide supplies

Industrial plants associated with the production of iron and steel products need a steady supply of black iron oxide. The reason is simple – black iron oxide contains the maximum amount of iron. Hence, it acts as a raw material for steel – an alloy of iron, carbon and other elements. This is one of the primary reasons why the atomic structure of steel bears a close resemblance to that of iron!

Iron oxide is used to produce colour pigments

Red iron oxide is known for its vivid red hue. Hence, it is used by paint and lacquer manufacturers as an additive to create red paint, lacquers and base coats.

Need quality assured, international grade iron oxide?

Contact Selective Minerals. Selective Minerals and Color Industries Pvt. Ltd. is an ISO 9001:2015 RINA certified company. The enterprise is also recognised by the Indian Government. It is an exporter of quality assured and international grade iron oxides and processed minerals. The company has been in the sector since 1991. For more details, feel free to call +91-022-26499343 / +91-99209 46444 or send an email to sales@selectiveminerals.com / info@selectiveminerals.com.