What is Iron Oxide? What are the Industrial Applications of Iron Oxide?

Iron oxide is a chemical compound that is iron as well as oxygen-rich. Iron oxide is found abundantly in nature. However, to keep input costs low, iron oxide is often produced in large quantities using synthetic procedures. The catch is that the overall quality of synthetic iron oxide always falls behind naturally derived iron oxide.

In terms of popularity and demand, as per revered iron oxide manufacturers, iron oxide happens to be the highest selling inorganic companioned worldwide.

To put things into perspective, the market share of iron oxide globally was 2 billion US dollars back in 2017. Since then, the market share of this inorganic compound has increased exponentially.

Industrial uses of iron oxide

The industrial uses of iron oxide are countless. However, the most popular ones are mentioned in the sections below –

It is the preferred ore for iron

According to the spokesperson of a reputed firm that supplies iron oxide in India, metal processing plants rely on quality assured iron oxide supplies as iron oxide contains a large quantity of iron in a diffused form. Hence, iron oxide acts as an ore for iron. On top of this, extracting iron from iron oxide is pretty seamless compared to extracting iron from other available ores.

Industrial plants associated with the production of steel also rely on companies that supply globally iron oxide from India. Without iron oxide, steel cannot be produced as steel is an alloy as it consists of carbon, iron and other trace elements.

It is used to produce iron oxide-based pigment

Iron oxide is also the primary raw material for industrial plants associated with the production of vivid red pigments. Vivid red pigment is commonly known in the industrial sector as ‘pigment red 101’ and without a steady supply of high-quality iron oxide, the global production of this industrial product will cease to exist.

The aforementioned pigment is used across the industrial spectrum. To put things into perspective, pigment red 101 is used as a colouring agent in cosmetic products. The pigment is also used by paint manufacturers as well as staining product manufacturers.

Iron oxide is also used in the automobile sector

Automobile companies use iron oxide to produce tint lacquers and clear coats in-house in a bid to keep input costs down.

Why add iron oxide on tint lacquers as well as clear coats?

Adding iron oxide in tint lacquers and clear coats enhance the molecular stability of the aforementioned. Iron oxide is also added to the paints used on automotive door handles and wheels in a bid to give the above-mentioned their signature transparent look.

Iron oxide is also used by automotive accessory manufacturers as an ingredient for the glass encasing of halogen bulbs used as turn indicators. The addition of iron oxide allows the turn indicator bulbs to have their signature amber hue.

Iron oxide is also used as an additive in polymeric fibres – the raw material that is used to manufacture automotive interior plastic trims. The addition of iron oxide to polymeric fibre-based automotive interior trims keeps them safe from UV damage.

Conclusion

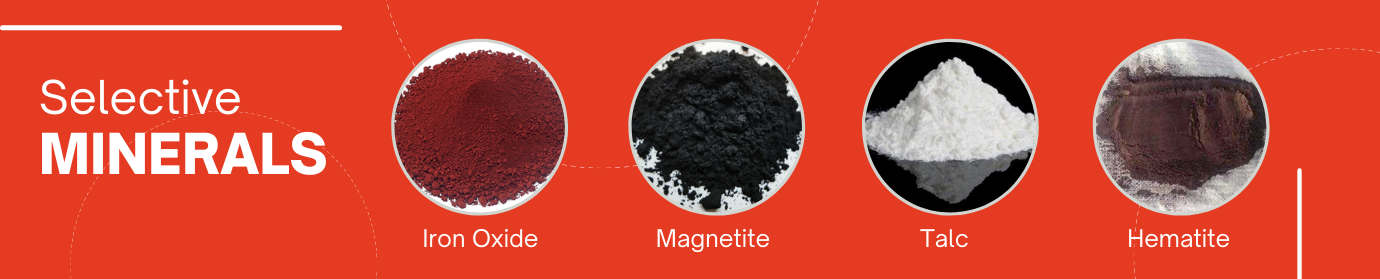

It would be unwise to partner up with a supplier that offers substandard iron oxide. Products manufactured using low-quality iron oxide will be of substandard quality. Hence, one can lose their reputation and market share before they know it! The best step forward is to partner up with veterans in the sector like Selective Minerals And Color Industries Private Limited. The company is based in Mumbai, India. It has a national and global footprint. It has been operating as a national and global supplier of iron oxide along with processed minerals, concrete colours, talc, magnetite and hematite powder since 1991. The best part, the company has ISO 9001:2015 RINA certifications. For more details, call +91-022-26499343/+91-99209 46444 or send an email to sales@selectiveminerals.com / info@selectiveminerals.com.